Finishing Feeders

|

Finishing Feeders

|

|

|

| Wean-To-Finish Wet / Dry Tube Feeder | ||

|

|

|

|

|

|

|

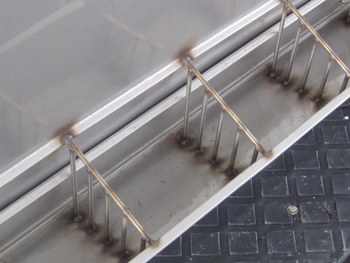

Stainless Steel Wean-To-Finish Dry Feeders With Divider Options |

||

|

|

|

|

|

|

|

||

|

Finishing Stainless Steel Dry Feeder Same options as Wean-to-Finish Dry Feeders with no divider option |

||

|

|

|

|

||

Note: This page is no longer being updated so some of the information above may be out of date. Please use these buttons to find current information.